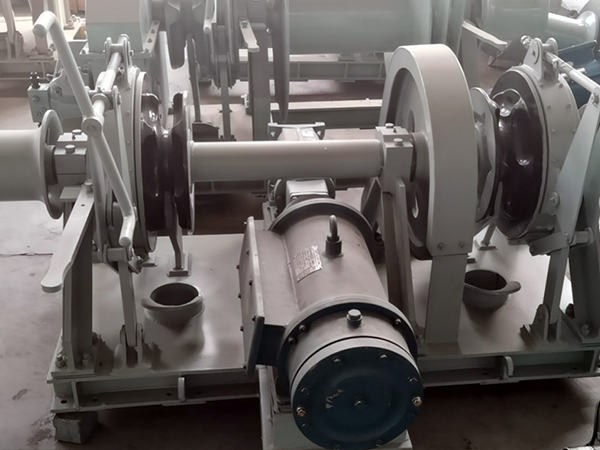

Electric windlass

| Elecric anchor windlass | ||||||||||||

| ||||||||||||

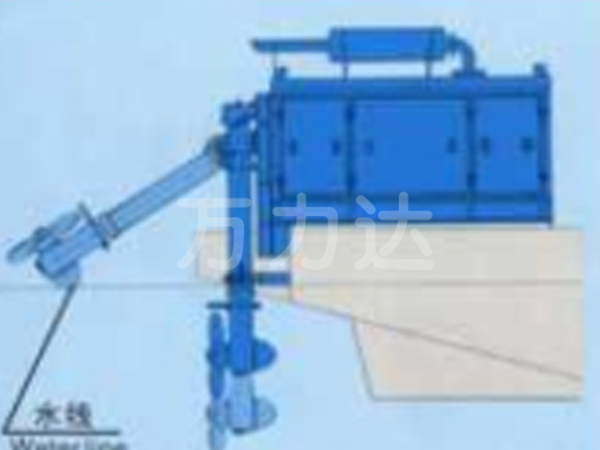

| An electrically driven windlass. Widely used in internal combustion engine ships. The picture shows a horizontal position. Principle of Electric Windlass: Windlass driven by an electric motor. Usually, the anchor and mooring winch form a linked unit, which is installed at the bow of the ship and used for lifting, anchoring, and mooring. The electric motor reduces speed through two stages of worm gear and gear, driving the winch shaft to rotate. A pair of sprockets are looped on the winch shaft and a pair of toothed clutches are installed with sliding keys. The clutch can slide axially through the handle, allowing it to fit or separate from the sprocket. When lifting the anchor, fit the clutch and sprocket, loosen the belt brake mechanism, and the cable winch can drive the sprocket to rotate; When anchoring, separate the clutch and sprocket, loosen the band brake mechanism, and then use the weight of the anchor to throw it out. Release the clutch and use the brake band to brake the sprocket. The cable winding shaft only drives the cable winding drum to rotate, which can be used for cable winding. Wanlida has a professional design team that develops and manufactures marine propellers. The products have the characteristics of stable performance, high efficiency, low noise, and simple operation. The company has passed the quality system certification and has been recognized by domestic and foreign classification societies such as CCS in China, BV in France, LR in the UK, GL in Germany, ABS in the US, RINA in Italy, DNV in Norway, NK in Japan, etc. For more information, please feel free to contact us: tina@wealidacn.com | ||||||||||||

| Main Performance Parameters | ||||||||||||

| 电动起锚机 Electric Anchor Windlass | 锚链直径 Chain Dia (mm) | 工作负载 Working Load (kN) | 支持负载 Support Load (kN) | 起锚速度 Working Speed (m/min) | 系缆负载 Warping Load (kN) | 电机功率 Motor Power (kW) | ||||||

| WDMΦ14/16/17.5 | 14/16/17.5 | 8.3/10.9/13.0 | 51/67/80 | ≥9 | 8 | 4.3/1.7 | ||||||

| WDMΦ19/20.5/22 | 19/20.5/22 | 15.3/17.9/20.6 | 95/110/126 | ≥9 | 10 | 8.5/3.5 | ||||||

| WDMΦ24/26 | 24/26 | 24.5/28.7 | 149/175 | ≥9 | 20 | 8.5/3.5 | ||||||

| WDMΦ28/30 | 28/30 | 33.3/38.3 | 202/231 | ≥9 | 30 | 11/11/7.5 | ||||||

| WDMΦ32/34 | 32/34 | 43.5/49.1 | 261/294 | ≥9 | 30 | 16/16/11 | ||||||

| WDMΦ36/38 | 36/38 | 55.1/61.4 | 329/365 | ≥9 | 30 | 22/22/16 | ||||||

| WDMΦ40/42 | 40/42 | 68.0/75.0 | 402/442 | ≥9 | 30 | 22/22/16 | ||||||

| WDMΦ44/46 | 44/46 | 82.3/89.9 | 483/526 | ≥9 | 30 | 22/22/16 | ||||||

| WDMΦ48/50 | 48/50 | 97.9/100.3 | 570/617 | ≥9 | 30 | 30/30/22 | ||||||

| WDMΦ52/54 | 52/54 | 114.9/123.9 | 664/713 | ≥9 | 50 | 30/30/22 | ||||||

| WDMΦ56/58/60 | 56/58/60 | 133.3/143.0/153 | 764/816/870 | ≥9 | 50 | 45/45/30 | ||||||

| WDMΦ62/64 | 62/64 | 163.4/174.1 | 925/982 | ≥9 | 50 | 45/45/30 | ||||||

| WDMΦ66/68 | 66/68 | 185.1/196.5 | 1040/1098 | ≥9 | 50 | 45/45/30 | ||||||

| WDMΦ70/73 | 70/73 | 208.3/226.5 | 1160/1254 | ≥9 | 50 | 60/60/45 | ||||||

| WDMΦ76/78 | 76/78 | 245.5/258.6 | 1350/1416 | ≥9 | 50 | 60/60/45 | ||||||

| Note: The above parameters and specifications are not fixed and can be designed according to customer needs. | ||||||||||||