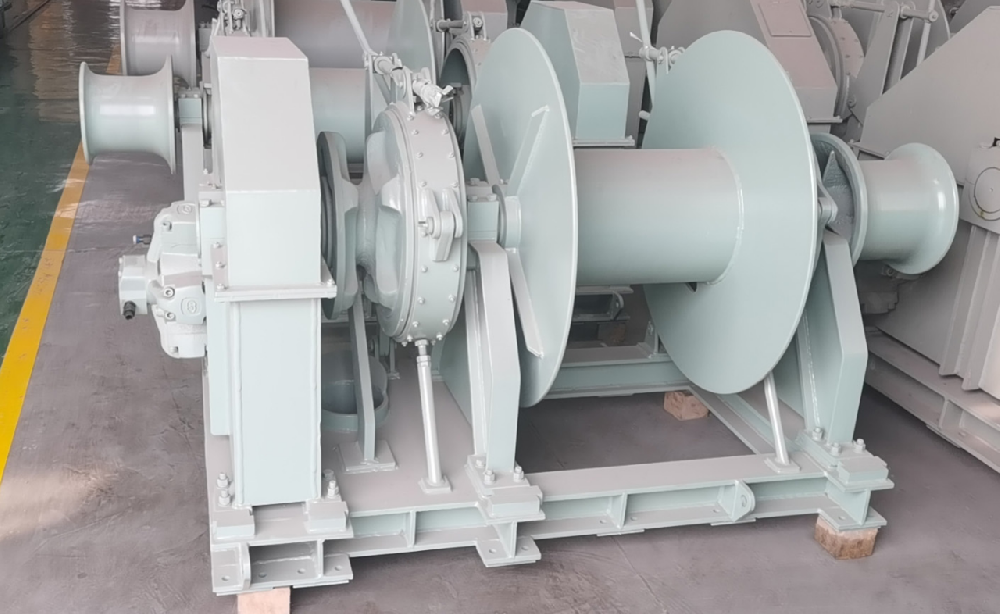

Hydraulic windlass

| Hydraulic anchor windlass | ||||||||||||

| ||||||||||||

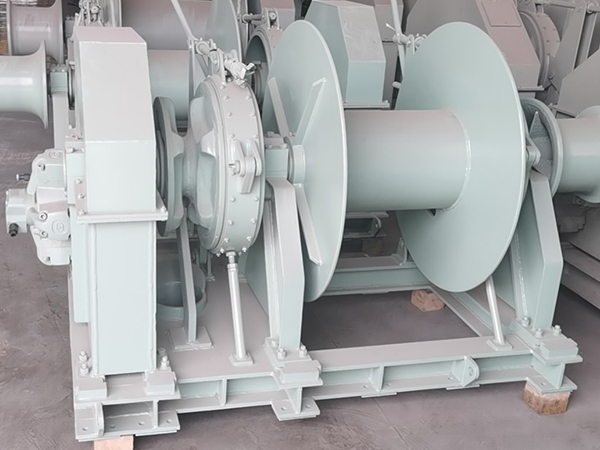

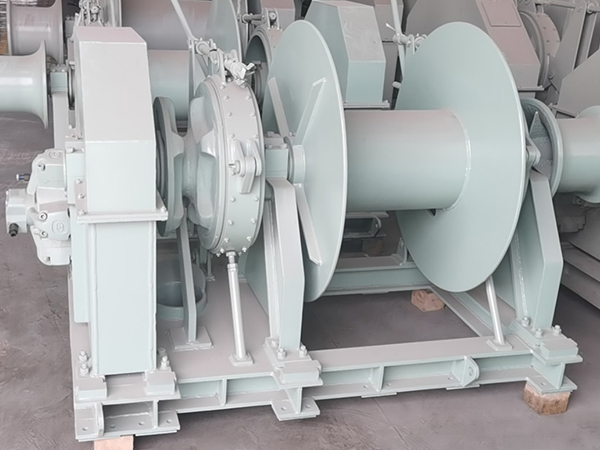

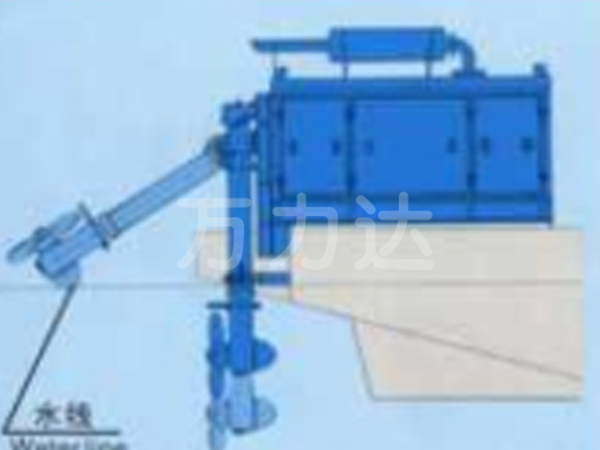

| Windlass is a mechanical device used on a ship to retract and release anchors and anchor chains. Using manpower, steam engines, electric motors, hydraulic motors, etc. as power. Usually installed on the bow deck of a ship. The development trend is to use a single unit to perform operations such as anchoring, mooring, automatic mooring, and mooring. According to the driving form, it can be divided into manual, electric, and hydraulic. Hydraulic anchor machine, also known as electric hydraulic anchor machine, is driven by an electric motor to drive an oil pump. The motor is driven by high-pressure oil, and then the transmission gear is driven by a reducer (or not equipped with a reducer) to operate the anchor machine. Its structure is relatively compact and its volume is small. The hydraulic anchor mainly consists of a base, bracket, anchor chain wheel, brake, sprocket, gearbox, hydraulic pump station, etc. The installation of the windlass on the ship should ensure that the angle between the anchor chain and the sprocket is 117-120 degrees. The types of anchor machines can be classified according to the diameter of the anchor chain φ 12-- φ Several specifications including 120mm. Wanlida has a professional design team that develops and manufactures marine thrusters and deck machinery equipment. The products have the characteristics of stable performance, high efficiency, low noise, and simple operation. The company has passed the quality system certification and has been recognized by domestic and foreign classification societies such as CCS in China, BV in France, LR in the UK, GL in Germany, ABS in the US, RINA in Italy, DNV in Norway, NK in Japan, etc. For more information, please feel free to contact us: tina@wealidacn.com | ||||||||||||

| Main Performance Parameters | ||||||||||||

| Hydraulic Anchor Windlass | Chain Dia (mm) | Working Load (kN) | Support Load (kN) | Working Speed (m/min) | Warping Load (kN) | Motor Power (kW) | ||||||

| WYMΦ24/26 | 24/26 | 24.5/28.7 | 149/175 | ≥9 | 20 | 11 | ||||||

| WYMΦ28/30 | 28/30 | 33.3/38.3 | 202/231 | ≥9 | 30 | 15 | ||||||

| WYMΦ32/34/36 | 32/24/36 | 43.5/49.1/55.1 | 261/294/329 | ≥9 | 30 | 22 | ||||||

| WYMΦ38/40/42 | 38/40/42 | 61.4/68/75 | 365/402/442 | ≥9 | 30 | 30 | ||||||

| WYMΦ44/46/48 | 44/46/48 | 82.3/89.9/97.9 | 483/526/570 | ≥9 | 30 | 45 | ||||||

| WYMΦ50/52/54 | 50/52/54 | 100.3/114.9/123.9 | 617/664/713 | ≥9 | 50 | 55 | ||||||

| WYMΦ56/58/60 | 56/58/60 | 133.3/143.0/153 | 764/816/870 | ≥9 | 50 | 55 | ||||||

| WYMΦ62/64 | 62/64 | 163.4/174.1 | 925/982 | ≥9 | 50 | 55 | ||||||

| WYMΦ66/68 | 66/68 | 185.1/196.5 | 1040/1098 | ≥9 | 50 | 75 | ||||||

| WYMΦ70/73 | 70/73 | 208.3/226.5 | 1160/1254 | ≥9 | 50 | 75 | ||||||

| WYMΦ76/78 | 76/78 | 245.5/258.6 | 1350/1416 | ≥9 | 50 | 90 | ||||||

| Note: The above parameters and specifications are not fixed and can be designed according to customer needs. | ||||||||||||