Telescopic crane

| Telescope Crane | ||||||||||||

| ||||||||||||

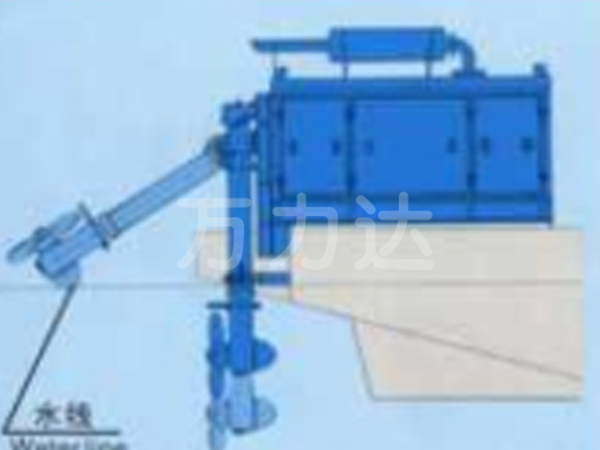

| Marine crane is a special type of crane used for transportation operations in the marine environment, mainly used for important tasks such as the transportation and transfer of goods between ships, maritime replenishment, and the deployment and recovery of underwater operation equipment. Hydraulic telescopic crane, compact in structure, can receive the minimum external dimensions of the lifting arm when not in use, suitable for storage on ships with limited space. The crane can be equipped with one or more telescopic arms. Specific specifications can be designed according to customer requirements. Various types of cranes can be selected: Remote control operating system Bridge operating system Sealed cab Hydraulic oil cooling or heating system Wanlida has a professional design team that develops and manufactures marine thrusters and deck machinery equipment. The products have the characteristics of stable performance, high efficiency, low noise, and simple operation. The company has passed the quality system certification and has been recognized by domestic and foreign classification societies such as CCS in China, BV in France, LR in the UK, GL in Germany, ABS in the US, RINA in Italy, DNV in Norway, NK in Japan, etc. For more information, please feel free to contact us: tina@wealidacn.com | ||||||||||||

| Main Performance Parameters | ||||||||||||

| Crane Type | SWL (T) | Working Radius max(M) min(M) | Hoising height (m) | Hoising Speed (m/min) | Luffing Time (s) | Slewing Speed (r/min) | Slewing range (deg) | Allowable heal (deg) | Motor Power (kw) | |||

| WQT1-6~10 | 1 | 6~10 1.5~2.2 | 30 | 15 | 50 | 1.5 | 360 | 5°/2° | 7.5 | |||

| WQT1.5-12~15 | 1.5 | 12~15 2.5~3.0 | 30 | 15 | 60 | 0.8 | 360 | 5°/2° | 15 | |||

| WQT2-6~10 | 2 | 6~10 1.5~2.2 | 30 | 15 | 50 | 1 | 360 | 5°/2° | 11~15 | |||

| WQT2-20~25 | 2 | 20~25 3.5~4.0 | 40 | 15 | 75 | 0.6 | 360 | 5°/2° | 18.5~22 | |||

| WQT3-8~15 | 3 | 8~15 2.0~3.0 | 30 | 15 | 60 | 1 | 360 | 5°/2° | 22 | |||

| WQT4-20~25 | 4 | 20~25 4.0~5.5 | 30 | 15 | 60 | 0.8 | 360 | 5°/2° | 37 | |||

| WQT5-15~20 | 5 | 15~20 4.0~5.5 | 30 | 15 | 60 | 0.8 | 360 | 5°/2° | 37 | |||

| WQT6-20~25 | 6 | 20~25 5.5~6.5 | 40 | 15 | 90 | 1 | 360 | 5°/2° | 45 | |||

| WQT8-20~30 | 8 | 20~30 4.0~6.5 | 40 | 15 | 90 | 0.6 | 360 | 5°/2° | 55 | |||

| WQT10-10~20 | 10 | 10~20 3.5~6.0 | 30 | 10 | 60 | 1 | 360 | 5°/2° | 55 | |||

| WQT12-16~20 | 12 | 16~20 4.0~7.0 | 35 | 10 | 90 | 0.8 | 360 | 5°/2° | 75 | |||

| WQT15-16~20 | 15 | 16~20 4.0~7.0 | 35 | 10 | 90 | 0.7 | 360 | 5°/2° | 90 | |||

| WQT20-25~30 | 20 | 25~30 5.0~8.0 | 45 | 10 | 150 | 0.5 | 360 | 5°/2° | 132 | |||

| WQT25-25~30 | 25 | 25~30 5.5~9.0 | 45 | 10 | 150 | 0.5 | 360 | 5°/2° | 160 | |||

| WQT30-25~32 | 30 | 25~30 6.0~9.5 | 45 | 10 | 150 | 0.5 | 360 | 5°/2° | 220 | |||

Note: 1. Motor power supply: 380V/50HZ/3Ph or 440V/60HZ/3Ph 2. This parameter table is for reference only, and specific specifications can be designed according to customer needs.

| ||||||||||||